Laboratory

Explore our Laboratory

ISO 17025 Analytical Testing

Every ingredient is tested for identity, purity and potency. This is done with precoder samples and at multiple locations throughout reception of raw material shipment through to finished product purity and potency verification.

Multidisciplinary Scientific Expertise

We believe in the benefits of science—and so does our team of 22 dedicated scientists. Our roster includes 3 PhDs, 7 MScs, and 12 BScs with specialties including biochemistry, food science and agricultural chemistry, chemical engineering, pharmaceutical sciences, and more.

On top of that, we employ 4 naturopathic physicians who all graduated from the Canadian College of Naturopathic Medicine in Toronto and have over 55 years of combined experience. Together, they use their knowledge and expertise to create innovative health products and ensure our quality is always second to none.

At the Crossroads of Science and Nature

All ingredients that enter our facility are tested three times over for identity, contaminants such as mycotoxins (aflatoxins), PCBs, over 80 different pesticides, heavy metals, microbiology (bacteria), mould, and fungus. Most importantly, we validate the potency. All these tests are conducted at our state-of-the-art, 8000 sq. ft. ISO 17025 accredited laboratory with 22 scientists, including 6 McGill University graduates. The laboratory, QC and QA is staffed by 3 PhDs, 7 MScs, and 12 BScs, who devote over 880 hours of testing and research weekly.

Unrivalled Testing

Our state-of-the-art, high-technology instruments achieve the most precise test results possible; we can detect down to parts per billion.

Stringent testing ensures the quality and safety of our products. You get what is on the label, nothing more, nothing less.

We put our faith in science, not in our suppliers. That’s why we invest in the most advanced technology and employ a team of 22 dedicated scientists to test each and every lot of each and every ingredient. Without compromise. It’s an expensive process that our competition simply is not willing to invest either the time or money into, but it’s vital to ensuring we are able to offer your customers the highest-quality, most effective products available.

Taking Quality to the Next Level

All of Our Products Are Subjected to the Following Quality Tests

Identity

To identify a plant ingredient is to ensure that the ingredient matches the species it is claimed to be; for example, it is borage seed and no other seed. Our testing always ensures that the ingredient matches the label.Potency

To confirm the potency of an ingredient is to ensure the ingredient is at the strength it is claimed to be; for example, grape seed will keep, contain, and meet the 95% proanthocyanidins label claim.Oxidation

Some products can go rancid with time. Our oxidation testing absolutely ensures our products maintain the highest levels of quality and freshness, as well as the lowest level of peroxide, all the way through to expiration.Disintegration

Capsules, softgels, and tablets must dissolve in the stomach; on the other hand, enteric-coated capsules, such as those of Acidophilus Ultra, must only dissolve in the intestines. Our disintegration testing mimics the human digestive system to ensure all products dissolve at the right place and at the right time.Purity

To establish the purity of an ingredient is to test for safety from contaminants. These contaminants include:- Heavy Metals: The Earth is permeated by natural levels of heavy metals. Ground crops are especially susceptible. Our testing guarantees the safety of our products.

- Over 80 different pesticides, total PCBs, solvent residues are tested. These chemicals are dangerous and can contaminate ingredients at any stage. Our testing absolutely ensures our products are safe from these contaminants and their dangers.

- Aflatoxins, mycotoxins, dioxins, microbial contamination: Testing only for microbial contamination is not enough. Our testing guarantees our products are safe from microbial contamination as well as of any residue these bacteria can produce.

This level of meticulous testing is only possible with the strongest scientific team equipped with the most technologically advanced equipment.

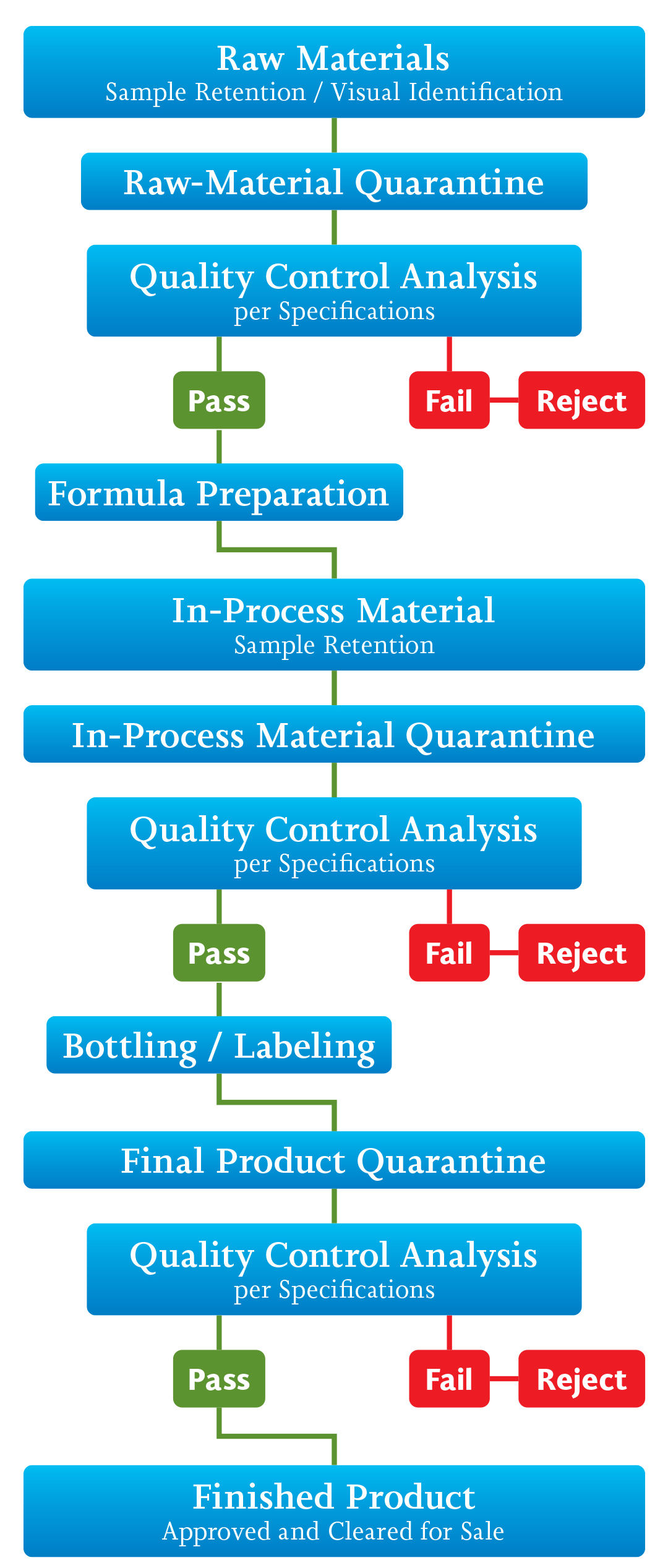

Manufacturing Flowchart

Overview of the world class equipment

in our Industry-Leading ISO 17025–accredited Laboratory

The laboratory includes 4 HPLCs, 4 UHPLCs, 2 GC-FIDs, 2 GC-MSs, 1 headspace, 2 spectrophotometers, 1 ICP-OES, 1 UPLC-MS/MS, 1 HPTLC, 1 NIR, and 1 microscope as well as a DNA extractor/purifier, DNA quantifier and a real time PCR unit.

-

Disintegration Tester

Internationally accepted by the US Pharmacopoeia, and employed by reputable scientists and researchers around the world, it effectively mimics exposure to harsh stomach acid. It is used to verify the integrity of our GPS™ enteric-coated capsule following exposure to destructive stomach acid. It also proves that competitors’ capsules leak and disintegrate, allowing stomach acid to destroy the probiotics within.

-

GC-Headspace

Residual solvents from extraction processes rank among the critical qualitycontrol concerns for natural health products. This machine is employed to guarantee the purity of all New Roots Herbal products.

-

ICP-MS:

Inductively Coupled Plasma

Mass SpectrometerSpecializing in identifying and quantifying metals and minerals, ICP‑MS validates their elemental quantities within formulas. It also detects low-level trace-metal contamination including mercury, arsenic, lead, and cadmium. This unique technology is able to detect compounds down to parts per trillion (10−12).

-

NIRS:

Near-Infrared SpectroscopeInfrared technology is used to identify raw materials thanks to the electromagnetic radiation absorbed from molecular bonds of molecules present in the sample. It differentiates genus and species.

-

UPLC/MS

(LC/MS-Triple Quad): Ultra‑Performance Liquid ChromatographDetermines identities and quantities of therapeutic marker compounds within botanical extracts. It’s also used for amino-acid identification and quantification. Ours can detect compounds down to parts per trillion (10−12) rather than parts per million (10−6) or per billion (10−9) like the competition.

-

GC-FID/MS:

Gas Chromatographs — Flame Ionization Detectors

Mass SpectrometersIdentifies and measures specific fatty acids present in Wild Omega 3, our industry-leading Wild Oregano C93, and exotic and essential oils. Its specific technology also detects the presence of impurities.

-

Spectrophotometers

This niche instrument employs intense light to measure enzymatic potency. Dynamic, naturally sourced enzymes including papain and bromelain require validation of biological activity before inclusion in New Roots Herbal formulas.

-

HPTLC:

High-Precision Thin-Layer ChromatographHTPLC is used to fingerprint the identity of different components within botanical materials. It is also used to detect fungal-based toxins.

-

QIACube

For DNA purification.

The QIAcube is a closed architecture liquid handling platform that is capable of almost fully automating the processing of 12 samples per run. -

Rotor-Gene Q Thermocycler

For GMO DNA detection and quantification by real-time PCR (qPCR). It combines multiple optimized design features to provide the outstanding performance and reliable results that our research and tests demands.

-

UHPLCs:

Ultrahigh-Performance Liquid ChromatographsThese versatile, high-precision machines determine both the identity and quantity of complex molecules, including fat‑ and water‑soluble vitamins. This allows us to identify and differentiate various compounds present in complex mixtures.

-

UV/VIS Spectrophotometer

For DNA quantification. It allows us to obtain the most complete information about the concentration and quality of our DNA, RNA, or protein samples.

Product Development

Our team is in constant motion, developing new products and improving existing industryleading formulas. We further invest in research and technology for advanced delivery systems such as our GPS™ enteric-coating system to protect probiotics from stomach acid. While delayed release and acid-resistant capsules leak and cause probiotics to be destroyed, our GPS™ enteric-coating system guarantees intestinal delivery of live probiotic cells. And that’s just one of the incredible innovations we are working on!

Technological Investments

Thanks to ongoing investments, the advanced technology in our ISO 17025–accredited, non‑GMO laboratory allows us to guarantee the identity, purity, and quality of our products. We are also able to detect and quantify genetically modified organisms using leading-edge, real-time polymerase chain reaction (PCR) testing. And no one else in the industry has our ability to test down to 1 trillionth of a gram (10−12 g). Our state-of-the-art production facilities allow us to increase production in-house while maintaining the high quality standards consumers have grown to trust. With all that, it’s not surprising that we’re able to attract the brightest minds in our industry, ensuring a better future for us all.

4 HPLCs

High-Performance Liquid Chromatograph

The HPLC is a master specialist in determining the identity and quantity of elements and molecules, such as the activity in an herb, the product of an enzymatic reaction, or any molecule which absorbs light or that can be made chromophore (able to absorb/transmit light). The HPLC is very specific in being able to absolutely determine what a substance is and exactly how much of it there is.

HPLC works by automatically injecting a small volume of liquid sample into a column packed with particles 1⁄20 the thickness of a white sheet of paper. The liquid sample is forced through the column by powerful micropumps. The detector sends a digital signal to the computer, where specialized software is used to identify and determine the quantity of the separated components.

We use it routinely to analyse the composition of compounds present in complex mixtures, such as water- and fat-soluble vitamins. We also use the HPLC to analyse a large variety of ingredient, for example astragalus, dandelion, and red clover.

This is a typical liquid chromatogram of water-soluble vitamins; these are called chromatographic peaks, and each one represents a separated compound.

4 UHPLCs

Ultra High-Performance

Liquid Chromatography

We’ve added 4 UHPLCs to our laboratory. These extend our extensive testing capability.

PCR Cycler: DNA GMO Identification

Our laboratory has also added DNA extraction and analysis capability. With this capability we can identify if an ingredient contains any GMO DNA or proteins.

UPLC/MS (LC/MS-Triple quad)

Ultra

Performance Liquid Chromatography Mass Spectrometer – Dual detector

If the HPLC is the master specialist in identifying and quantifying, then the LC-MS/MS is the all-star. It is able to do everything the HPLC can do, only better and more precisely. It does this by using a very high-pressure micropump—15,000 psi—,combined with dual detector / photodiode array (PDA) and a more powerful mass spectrometer detector. It is used in cases where extreme sensitivity is needed.

Currently, this is the most advanced and widest-application tool for analysis. It allows for the most precise measurements—in parts per trillion rather than billion or million… The LC-MS/MS is able to effectively analyse herbs and medicinal components.

The LC/MS combines the advanced separation capabilities of an HPLC with the powerful analytical abilities of a mass spectrometer.

A sample is injected into the UPLC system and separated into its various components. These components enter the MS through an “electro spray interface,” where very rapid ionization takes place. At this point, the mass spectra of the components can be used to pinpoint-analyse the sample.

The main advantage of this system is that it generates fast, accurate, and extremely precise measurements by creating an electronic signature of a compound. We test many nutraceuticals with this instrument, such as glycosides in black cohosh, thujone in worm wood, and residual antibiotics in royal jelly.

2 GC-FID/MSs

Gas

Chromatography–Flame Ionization Detector/Mass Spectrometrer

The GC is used to analyse volatile molecules with a high melting point, such as fatty acids in fish oil. In addition, samples submitted to the GC do not need solvents or a “liquid mobile phase”; instead, samples are carried by an inert gas through the system. Hence, if we are testing for solvents, the instrument of choice is the GC-FID/MS; no steps are needed to factor out any solvents used to prepare the sample.

GC-MS is precisely able to identify and determine the quantity of the molecules of interest, whereas GC-FID is only used to determine the quantity of molecules. Like LC-MS/MS, GC-MS is also able to create an electronic signature of a molecule. The complexity of running the test will dictate which instrument will be used.

In a GC system, the vaporized sample is moved with a carrier gas through a specially coated capillary column. The column separates the components before entry into the detector; in our case, either the FID or MS, depending on the application.

We also use the GC-FID system to determine the quantity of common fatty acids and essential oils present in oils such as tamanu, argan, and fish oil.

This is a typical fatty acids chromatogram of an argan oil sample.

PCBs and pesticides are tested for through the GC-MS. As the samples pass through the ionization chamber, they are bombarded with a very high voltage of electricity that results in complete fragmentation (separation) of the individual compounds. The fragments are reconstructed as they move through a vacuum tube as per their mass-to-charge ratio. The given signal is recorded by the computer for analysis.

The compounds are compared with a well-known library from the National Institute of Standards and Technology (NIST) or a certified reference standard material.

The total ion chromatogram below represents a pesticides mixture.

Samples being tested for solvents pass through our headspace GC-FID. The FID incinerates the sample, giving an electrical signal for analysis. We use this setup to detect if there are solvents, such as 1,2-dichloroethane and 1,1,1-trichloroethane—which are known human carcinogens. These contaminants can be present in low-quality herbal extracts, and we have zero tolerance for them.

The chromatogram below represents residual solvent.

ICP-OES

Inductively Coupled Plasma–Optical Emission SpectroscopyICP specializes in analysing metals and minerals. With this device, we can effectively and precisely determine the identity and quantity of any metal present in a sample, be it iron, magnesium, lead, mercury, or boron. The process to test for these metals is much more straightforward than it would be on the HPLC or LC/MS.

With an ICP-OES, a sample flows into a plasma torch, where it is incinerated into atomized particles. Electrons of the atomized sample go through different levels of energy and by doing so, the atoms emit light; that light is analysed for meaningful information.

We use it to detect contamination by low-level trace metals—including mercury, arsenic, lead, and cadmium. These contaminants permeate the Earth’s crust and can be especially present in foodstuff grown in the ground or any items originating from the earth.

Essentially, the only remnants of an atomized sample will be any residual metals, which we are then able to detect. This makes methods developed to test metals easier to run for on the ICP.

Here is an ICP screenshot of the spectral view of cadmium.

2 Spectrophotometers

The spectrophotometer is a cost-effective tool that can be used to determine the quantity of samples which absorb or transmit light. Based on absorption or transmittance of light, a correlation can be made to determine the quantity of a substance. The identity of the sample will be determined through other instruments.

A spectrophotometer is a device used to measure light intensity. NASA typically includes a spectrophotometer on their interplanetary landers such as the Spirit and Opportunity rovers. A small beam of light passes through the sample; some of the light is absorbed, but what passes through is detected and measured by the spectrophotometer. We are able to use this information to determine the quantity of a substance.

Our spectrophotometer is used to determine some enzymatic activities, such as papain and bromelain, or anthocyanidin content in bilberry.

Here is a screen shot of a spectrophotometer graph of a papain sample.

HPTLC

High-Precision Thin-Layer ChromatographThe HPTLC is an effective tool to verify the fingerprint of identity of ingredients against a reference plate. We are able to confirm the profile of a plant thanks to this tool, and to ensure the right ingredient is being used.

With an HPTLC, individual components of a mixture are separated on a thin glass-coated plate, which is then placed in a developing chamber. The TLC plate is placed under an ultraviolet lamp, and bands of the different components are visualized. Unlike a standard TLC, with an HPTLC many tasks are automated via robotics, eliminating uncertainty from samples being applied to plates by hand.

We use the HPTLC to detect if products have been contaminated by mycotoxins, a dangerous class of toxins that can develop on plant matter in humid conditions.

You can see an HPTLC plate below.

NIR

Near-Infrared SpectroscopyNIR can be used to test a wide variety of substances; herbs and isolates such as amino acids. NIR can test almost anything, so long as we have a sample known to be that substance. With this device, we can guarantee the freshness of the plants we use in your product.

NIR works by comparing the fingerprint of a substance with an average of fingerprints of samples known to be that substance. Those fingerprints form a 3D reference model of what is acceptable. This is important, as even grown under similar conditions, the same plant will not grow in an identical fashion.

NIR allows us to identify herbal products’ total quality. We ensure that only those samples that meet our strict criteria for freshness and quality are able to pass. We only include the highest-quality herbals in the reference models we create for the NIR.

The NIR gives a reliable identification of a sample by comparing its spectra to the spectra of a sample of known characteristics. NIR analyses the transmissive properties of specific wavelengths of light in the sample being measured.

Here is a representation of spectral information into a three-dimensional image.

Microscope

The venerable microscope is still a staple in any laboratory. Of course, we use a modern light microscope; this style of microscope utilizes a focused beam of light that is converged by the condenser lens onto a specific point on the specimen. We use it to examine the broken cell status of Chlorella samples.

Here is an example of a broken cell wall in a Chlorella sample; broken cell walls make for easier digestion and absorbability.

.jpg)

NexION® 2000 ICP-MS

The NexION 2000 Inductively Coupled Plasma Mass Spectrometer (ICP-MS) is very versatile. It features an array of unique technologies that combine to deliver the highest performance no matter the analytical challenge. Its versatility makes it easy to handle any sample matrix and address any interferences; It accurately measures sub-ppt levels of critical trace elements such as Na, K, Ca, and Fe.

It is coupled with a prepFAST MC™ which is a fully automated, low pressure chromatography system that isolates elements of interest from the sample matrix and collects multiple discrete eluent fractions for precise isotopic analysis. This allows for example the separation of organic arsenic from inorganic arsenic.

BIG NEWS!

New Microbiology Department

New Roots Herbal is committed to continuously invest into our industry-leading ISO 17025–accredited laboratory to ensure customers receive the highest-quality, purest, most potent, and safest products.

Therefore, New Roots Herbal is pleased to announce the opening of a new microbiology department in our in-house laboratory. This is yet another important milestone in our development that enables our lab professionals to analyze microbiological attributes of different raw materials and finished products according to USP standards, which is of crucial importance for quality assurance. Some of these attributes include total microbial aerobic, yeasts and molds count, including detection of pathogenic species such as Enterobacteriaceae, E. coli, Salmonella, Pseudomonas aureus, and Staphylococcus aeruginosa.

In addition to the core chemistry and enzymology section, the GMO section, with the newly opened microbiology unit, allows our laboratory to provide complete analytical services for all New Roots Herbal products.

The new microbiological department is comprised of a wide array of equipment including two autoclaves for the eradication of microorganisms, 4 microbiological incubators (1 with humidity-control option), a cryogenic freezer (designed for long-term storage of biological materials, samples, and specimens at ultralow temperature), two laminar air flows to reduce and control viable and nonviable particulates, a biosafety cabinet, and an industry-specific colony-counting microscope.

The new microbiological department also features the VITEK 2 Compact (automated microorganisms identification system), which offers a state-of-the-art technology platform for phenotypic identification methods employed for detection of Enterobacteriaceae, E. coli, Salmonella, Pseudomonas aureus, Staphylococcus aeruginosa, etc. in samples.

This is yet another milestone in providing reliable testing methods in our in-house laboratory to ensure results we can trust and fully stand behind.

New Roots Herbal is proud to say that we conduct our entire roster of tests in our ISO 17025–accredited lab in accordance with USP standards and with product quality, potency, and purity as well as consumer safety as our highest priorities.

Stores

Stores